Factory Source Hydraulic Scrap Metal Shear - Car Dismantling Shear Excavator Ship Crushing Shears – Donghong

Factory Source Hydraulic Scrap Metal Shear - Car Dismantling Shear Excavator Ship Crushing Shears – Donghong Detail:

description

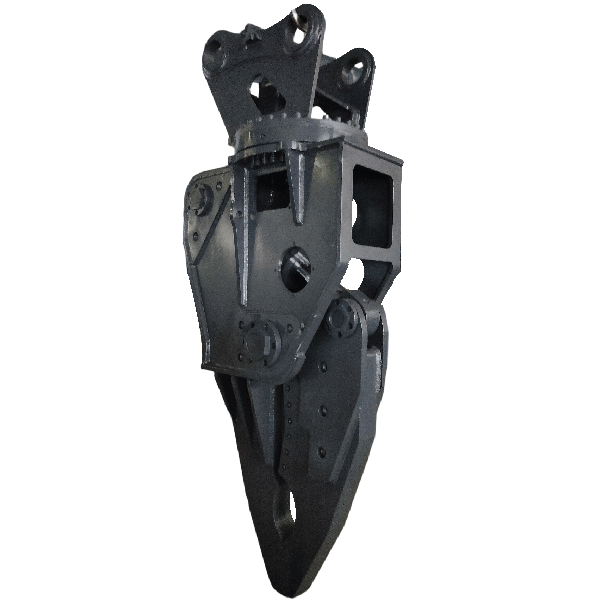

Like a vulture would dissect its prey, the clamp arms pin down the vehicle to allow the grapple to systematically pull the valuable materials away from the lower value vehicle body shell. The knife blades on the clamp arms allow engine and transmission assemblies to be split from the engine block.

characteristic

The ultimate combination of power and dexterity. The grapple features a slender, plier-like shape providing an unbroken line of sight from the operator to the vehicle, allowing valuable materials such as the copper wiring loom to be extracted from even the tightest of areas. High power hydraulic cylinders and high torque rotation unit give the shear the power to effortlessly dissect the vehicle.

significance

We understand that in a demanding, fast paced industry, productivity is paramount. That is why the shear is built to work, all day, every day. Manufactured 100% from high strength steels so that you can maximize your profits without the worry of downtime.

Dismantling Shear is usually installed on excavators and are widely used for dismantling scrap cars, dismantling factory steel structures, ship breaking, cutting steel bars, steel, tanks, pipes and other scrap steel.

use

And we would like to introduction our Donghong hydraulic scrap shear:

(1)Wear resistance steel has high strength, light weight and large shear force.

(2)The pin shaft adopts 45 carbon steel with built-in oil passage, high strength and good toughness.

(3)Adopt import rotary motor

(4)The oil cylinder adopts honing pipe and imported oil seal, with short working period and long service life.

(5)The cutter block is made of wear-resistant alloy steel, which is resistant to high temperature and deformation.

(6)The design of hooking angle can make it easier to hook the material “straight into the sharp knife” and cut off the structural steel. It is suitable for the disassembly of heavy vehicles, metal ships in steel mills, bridge decomposition and other steel structure facilities.

360 degree rotating tool-powerful rotation torque enables effective twisting and stripping motions via the proportionate control button on the left joystick. Movements are quick, controlled and precise. Powerful crushing force – The interlocking replaceable teeth are made to grip and hold material securely, yet nimble enough to grab and pick up a single wire. Special jobs require specially equipped machines. So we engineered these specialty excavators to take on unique applications that no ordinary excavator could touch. Donghong produced Hydraulic Steel Shears, car dismantling equipment matched kinds of excavators to satisfy customer’s demands.

specification

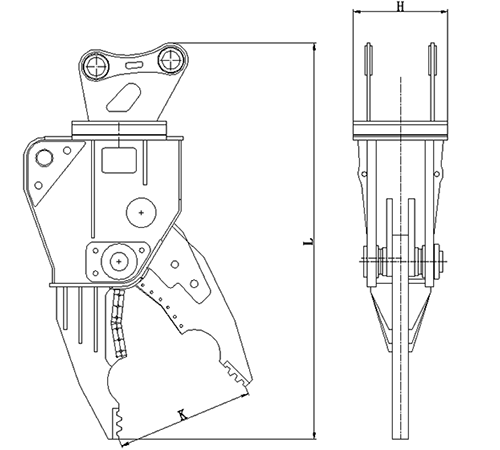

| technical specification | ||||

| Model | Unit | 06 | 08 | 10 |

| Weight | ton | 14-17 | 18-25 | 26-35 |

| Opening Size | mm | 670 | 840 | 960 |

| Length | mm | 2020 | 2530 | 2950 |

| Width | mm | 650 | 820 | 950 |

| The blade length | mm | 170*2 | 200*2 | 220*4 |

| Maximum cutting force | ton | 160 | 208 | 249 |

| Actuating Pressure | kgf/cm² | 250 | 280 | 249 |

| Actuating Flow | L/min | 180-190 | 200-240 | 230-260 |

| Rotary motor pressure setting | kgf/cm² | 100 | 100 | 100 |

| Rotary motor pressure flow | L/min | 20-30 | 20-30 | 20-30 |

| Rotation speed | r/min | 10-12 | 10-12 | 10-12 |

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Factory Source Hydraulic Scrap Metal Shear - Car Dismantling Shear Excavator Ship Crushing Shears – Donghong , The product will supply to all over the world, such as: Amman, Uruguay, France, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!