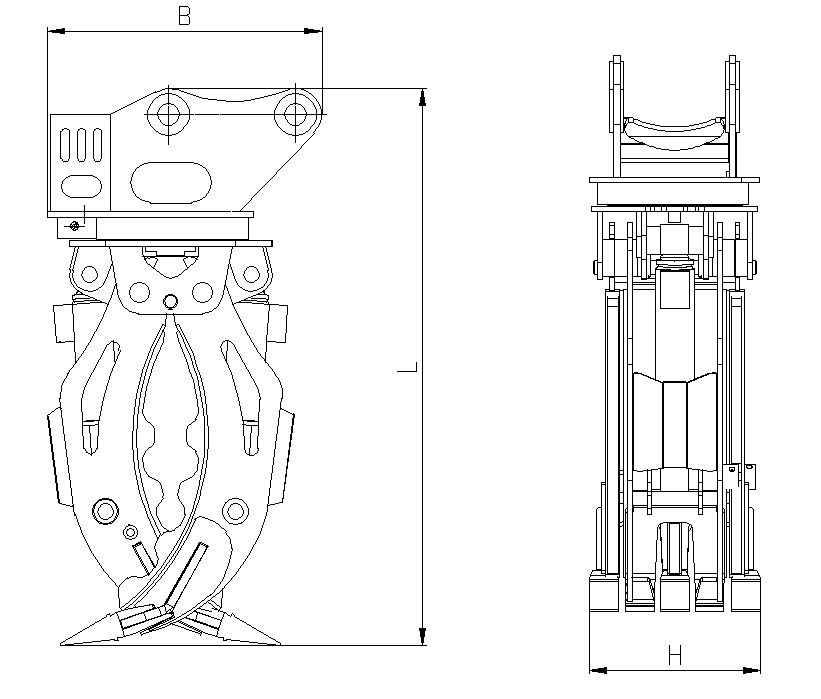

Excavator hydraulic grapple rotating wood stone grab for excavator

product

The word “Grapple” comes from a tool that has helped the French winemakers grab the grapes. Over time, the word grapple turned into a verb. In the present times, the workers utilize the excavators to grapple things around the construction and demolition site.

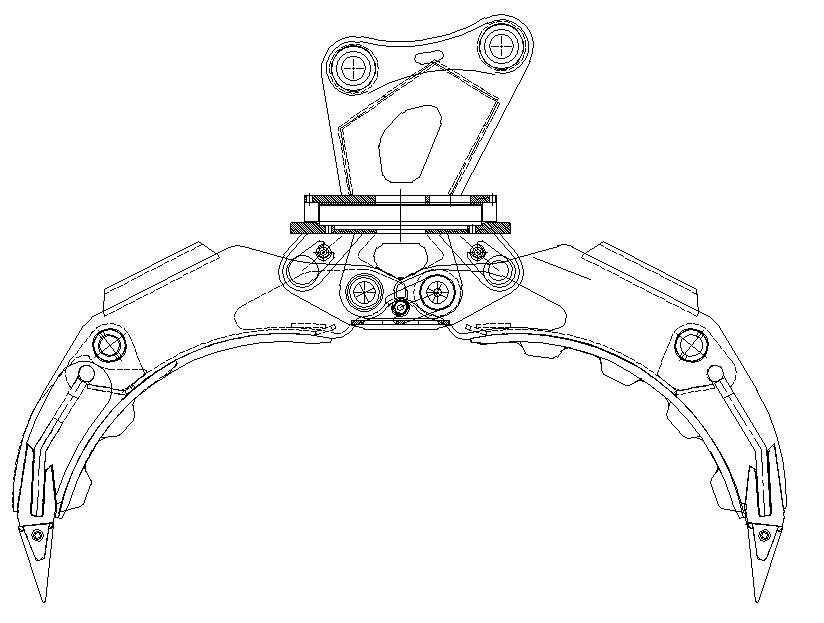

Log/Stone Grapple is a kind of excavator attachments which is mainly used for wood, log, timber, stone, rock and other large scraps handing, moving, loading and organizing.

As one of the leading Log Grapple manufacturer in China, DHG has a full range of log grapples for excavator. They are suitable for all kinds of brands and models of excavators. Application area: Wood, log, timber, stone, rock and other large scraps handing, moving, loading and organizing

Description

What is the difference between a mechanical and hydraulic type grapple?

One of the key decisions to make is whether you need the mechanical or the hydraulic grapple for the excavator.

Mechanical grapple:

Mechanical grapples utilize the bucket cylinder to perform the operations. It does so when the cylinder’s opening movement opens up the jaw’s tines.

The mechanical grapples need less maintenance compared to hydraulic grapples.

Now, the question remains; what kind of job is most suited to a mechanical grapple? Well, the stiff arm attached to the dipper arm of a mechanical grapple can lift the huge weight, move around the scrap, and be a perfect fit for heavier jobs.

Hydraulic Grapples:

On the other hand, hydraulic grab gets all the energy from the excavator. The hydraulic circuit of the machine is attached with the grapple jaws, which move the tines in synchronization. The hydraulic grabs for excavators are considered more efficient and precise in movement.

Hydraulic Grapples can even move at an angle of 180-degrees to provide you complete freedom of action on the job site. So, we can say that hydraulic grapples are meant for freedom of movement and precision.

After reviewing the significant contributing factors, you can now decide what sort of grapple is appropriate for the task you will accomplish. Whether it’s the construction site where you need to move the heavy stones or the demolition site where you need to clear the debris off the site, the excavator grapple attachments let you maximize the productivity on site.

| Model | Unit | DHG-04 | DHG-06 | DHG-08 | DHG-10 |

| Suitable Weight | ton | 4-8 | 14-18 | 20-25 | 26-30 |

| Jaw opening | mm | 1400 | 1800 | 2300 | 2500 |

| Weight | kg | 350 | 740 | 1380 | 1700 |

| Working pressure | kg/cm² | 110-140 | 150-170 | 160-180 | 160-180 |

| Setting pressure | kg/cm² | 170 | 190 | 200 | 210 |

| Oil flow | IPM | 30-55 | 90-110 | 100-140 | 130-170 |

| Cylinder | litre | 4.0*2 | 8.0*2 | 9.7*2 | 12*2 |

Product features

1. Using special steel, light in texture, high elasticity and high wear resistance;

2. The maximum gripping force of the same level, the maximum opening width, the minimum weight and the maximum performance;

3. The oil cylinder has a built-in high-pressure hose and maximum protection hose; the oil cylinder is equipped with a cushion, which has the function of damping;

4. Use special rotating gears to extend product life and reduce maintenance costs.

How to choose the grapple?

1.Make sure of the weight of your carrier.

2.Make sure of the oil flow of your excavator.

3.Make sure of the wood or stone which you want to carry.

The warranty of our RAY Grapple:

The warranty of these spare parts is 12 months. (Body, Cylinder, Motor, Slewing Bearing, Splitter, Safety Valve, Pin, Oil hose)

After service

1. Construction agent system for worldwide to give the end customers best service.

2. Perfect after-sales service, every once in a while to ask some feedback from customer in order to provide better service.